|

RKM(HUIZHOU)CONVEYOR SYSTEM CO., LTD

|

GCS mining conveyor impact roll/Buffer roller set suitable for coal mine transportation/Belt conveyor Images

| Price: | 50.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Product Details:

Place of Origin: HUIZHOU,China

Brand Name: GCD,RKM

Certification: ISO9001:2015

Model Number: conveyor belting Mackay

Payment & S

Product Details:

| Place of Origin: | GuangDong,China |

| Brand Name: | GCS,RKM |

| Certification: | ISO9001:2015 |

| Model Number: | Roller Set |

Payment & Shipping Terms:

Minimum Order Quantity:Price:Packaging Details:Delivery Time:Payment Terms:Supply Ability:

| mining conveyor impact roller sets FOB Reference Price:Get Latest Price US $10-50 / Pieces | 10 Piece/Pieces mining conveyor impact roller sets (Min. |

| mining conveyor impact roller sets FOB Reference Price:Get Latest Price US $10-50 / Pieces | 10 Piece/Pieces mining conveyor impact roller sets (Min. |

| wooden box mining conveyor impact roller sets |

| 10-20Days ShenZhen Port |

| L/C, T/T |

| 100000 Piece/Pieces per Month mining conveyor impact roller sets |

Product Description

mining conveyor impact roller sets

Product Application

Our products are widely used in thermal power generation, harbours, cement plants, metallurgy and as well as the light duty conveying devices for industries.

RKM-NS Model addes a sealed cover in its design. The distance between the sealed cover and bearing provides the bearing with a dust proof to ensure a longer working lift. This design is suitable for a normal working environment.

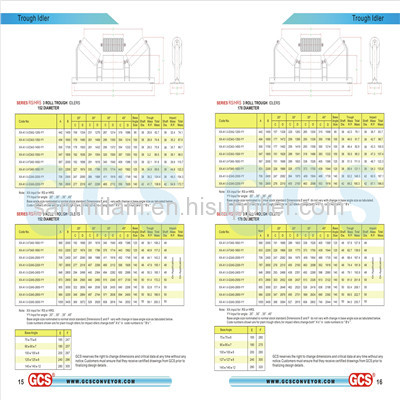

| SPECIFICATIONS | |||

| Diameter | φ89, φ102, φ108, φ194 | ||

| Length | 145mm-2800mm | ||

| Tube | Q235(GB), Q345(GB), welded with DIN2394 standed | ||

Shaft

| A3 and 45# steel(GB) | ||

| Bearing | Single & Double Row Deep Groove Ball Bearing 2RS&ZZ with C3 clearance | ||

| Bearing Housing/Seat | Cold press working fit ISO M7 accuracy Deep Press steel with raw material fit DIN 1623-1624 standard | ||

| Lubricating Oil | Grade 2 or 3 long-lasting lithium greasae | ||

| Welding | Mixed gas shielded arc welding end | ||

| Painting | Ordinary painting, hot galvanized painting, electric static spraying painting, baked painting | ||

Main Features

1) Solid design, suitable for heavy lifting.

2) The bearing housing and steel tube are assembled and welded with a concentric automatic.

3) Cutting of the steel tube and bearing is performed with the use of a digital auto device/machine/equipment..

4) The bearing end is constructed to ensure that the roller shaft and bearing can be firmly connected.

5) Fabrication of the roller is effected by an auto device and 100% tested for its concentricity.

6) Roller and supporting components/materials are manufactured to DIN/ AFNOR/ FEM/ ASTM/ CEMA standard.

7) The casing is manufactured with highly composite, anti corrosive alloy.

8) The roller is lubricated and free from maintenance.

9) Woring life expectancy is up to 30,000 hours or more, depending on usage.

10)Vacuum sealed which has withstood anti water, salt, snuff, sandstone and dust proof experiments